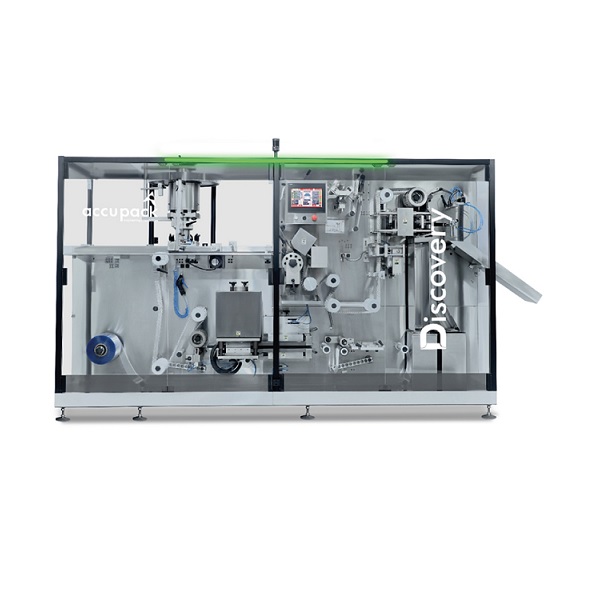

Blister Packaging Machine Discovery

Blister Packaging Machine Discovery van Accupack: Ontdek echte prestaties met een uitvoer die servogestuurde indexering biedt en een hoge compatibiliteit met de belangrijkste wisselstukken voor roterende machines.

De hoogwaardige Blistermachine van Accupack heeft een ergonomisch ontwerp dat een hoge veelzijdigheid en compatibiliteit combineert met een geavanceerde mens-machine-interface voor totale controle en maximale uitvoer.

PRODUCTKENMERKEN

USP

- Ultracompact ontwerp: lijnlengte 6,5 m

- 300 blisters/min

- Operatorvriendelijk ontwerp

- Uitzonderlijke prijs-/prestatieverhouding

- Wisselen zonder gereedschap

- Onderhoud op afstand

BELANGRIJKSTE KENMERKEN

- Europees ontwerp

- Een volledig servogestuurd mechanisme voor hoge nauwkeurigheid en efficiëntie

- Ideaal voor veelvuldig wisselen

- Kleine en lichte onderdelen

- Ingebouwde plughulp voor ingewikkelde vormen en speciale materialen

- Meerdere toevoeroplossingen

- Speciaal reliëfstation

- Eenvoudig te reinigen dankzij cGMP-conform balkonontwerp

- Klaar voor integratie in kartonnage

- Lage levenscycluskosten

- Uitstekende levertijden dankzij slanke productieprocessen

- 24/7 service concept

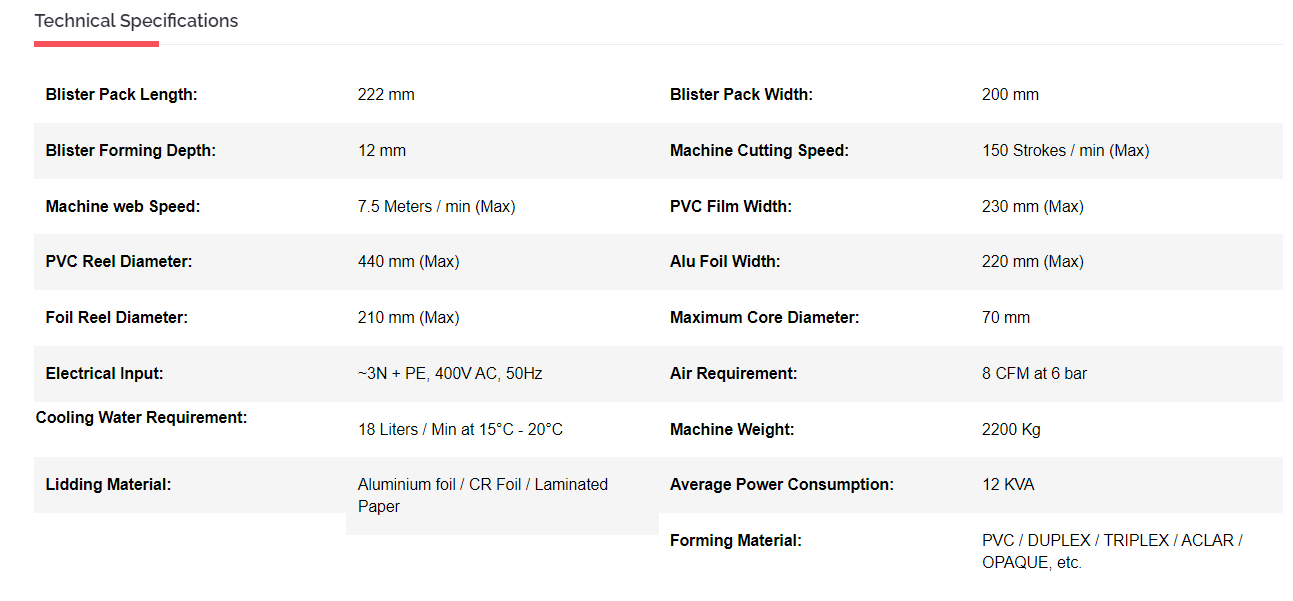

TECHNISCHE SPECIFICATIES

- Output (Max): 300 blisters/min

- Werkingsmodus: Dubbele baan

- Sealprincipe: Rolverzegeling

- Blisterverpakkingslengte (max): 222 mm

- Blisterverpakking Breedte (Max): 90mm

- Voorschot (Max): 200mm

- Diepte blisterverpakking (max): 12mm

- Thermovormmateriaal: PVC, PVC/PVDC, Duplex, Triplex, PVC/Aclar, PP

- Dekkend Materiaal: Hard Al, Zacht Al, Document Al, CR folie, Gelamineerd Document

- Snijsnelheid machine (Max): 150 slagen/min

- PVC-film breedte (Max): 230mm

- Alu folie breedte (Max): 226mm

- Gewicht: 2200kg

Accupackeurope_portfolio_overview

Accupack Engineering Private Limited is het grootste bedrijf in Azië voor oplossingen op het gebied van farmaceutische productie.

Met meer dan 20 jaar ervaring weet Accupack dat tijd en kosten een belangrijke rol spelen bij het voldoen aan de toenemende eisen van de klanten in de farmaceutische industrie. Daarom hebben ze de industrie opnieuw gedefinieerd met de mogelijkheid om te werken in hun meest efficiënte en geoptimaliseerde vorm door middel van onze oplossingen, waaronder blistermachines, kartonneermachines en software voor operationele intelligentie - PLEXUS.

DE GRENZEN VAN DE TECHNISCHE MOGELIJKHEDEN VERLEGGEN

Gedreven door innovatie verkennen en verleggen ze de grenzen van de technische mogelijkheden met behulp van de nieuwste state-of-the-art technologie. Met meer dan 300 succesvolle installaties in de afgelopen 5 jaar zijn deze blister- en kartonneermachines toonaangevend in de industrie. Ze streven ernaar om agressief te transformeren en een niche voor onszelf te creëren op de wereldmarkt in de productie van formaatdelen en blistermachines.